POPULAR PRODUCTS

CUSTOM DESIGN OPTIONS

Whether you need a replacement block or a new unique block for your project, Lethiguel is your

solution source for any of your custom needs.

Custom designs and alternative formats include: Custom Dimensions, Corner Radii, Double

Flow Areas, Ejection Pin Holes, Custom Water Lines and Steps.

NEWS

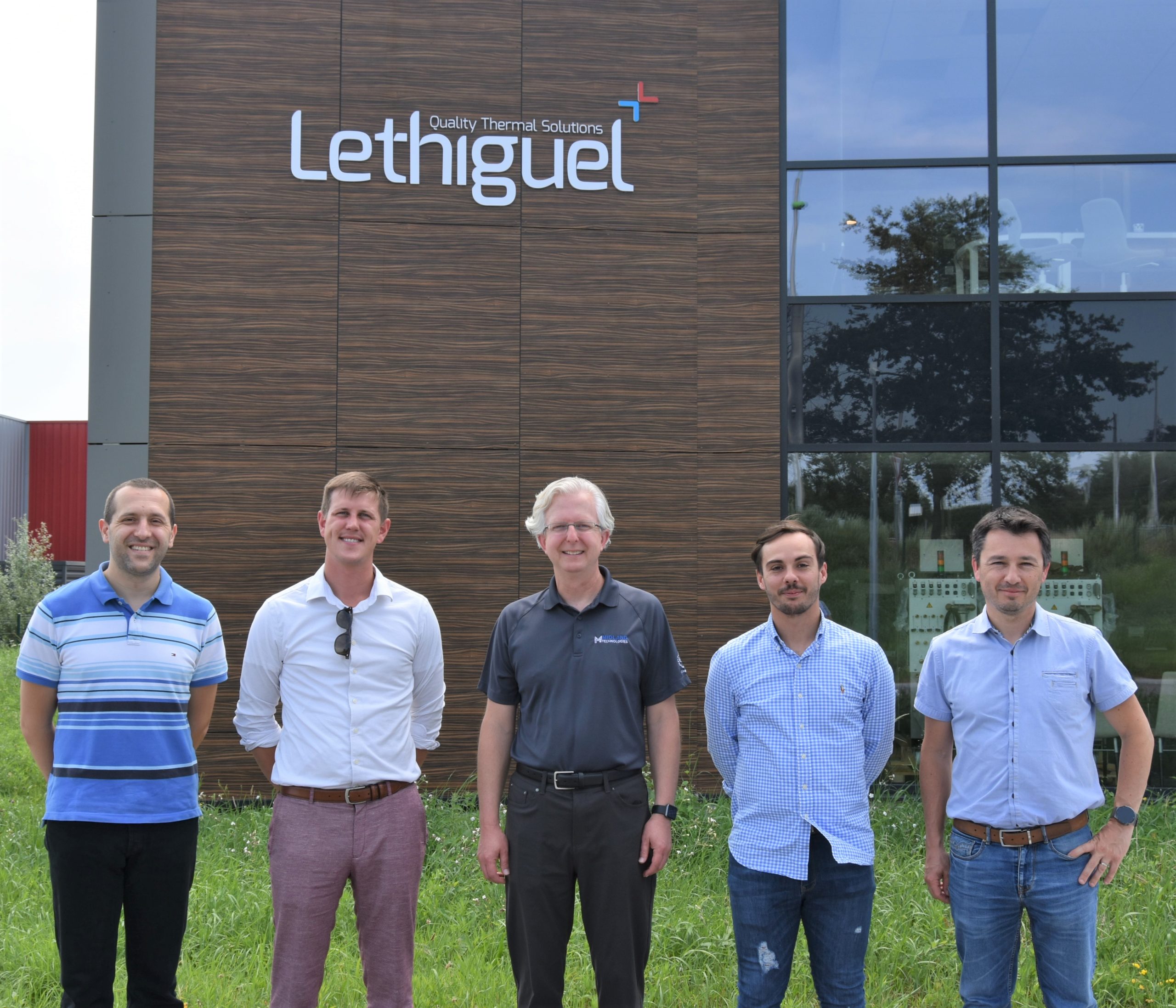

Midland Technologies is now Lethiguel USA

Lethiguel SAS announced the complete acquisition of Midland Technologies Inc in 2021 This strategic move is to lead the group to the double benefit of a strategic industrial establishment in the USA, and the acquisition of complementary technology [...]

Company update: Midland Technologies joined Lethiguel family

Lethiguel SAS announces complete acquisition of Midland Technologies Inc. Lyon, July the 5th: Lethiguel company, a French firm operating in the light metal casting industry, has acquired a 100% stake in Midland Technologies Incorporated, Minneapolis-based casting solution provider [...]

Reducing Porosity: High Pressure Die Casting

A common method of manufacturing parts is through high pressure die casting. This method is popular due to manufacturers’ ability to rapidly make complex parts at high volumes. However, high pressure die casting does cause gas porosity, and [...]